Contact Lens

Background

The contact lens is a device worn in the eye to correct vision, although some people wear colored contact lens to enhance or change their eye color. The thin plastic lens floats on a film of tears directly over the cornea. For some forms of eye disease, contact lenses correct vision better than conventional spectacles. Many people prefer contact lenses over glasses for cosmetic reasons, and active sports enthusiasts prefer contact lens because of the freedom it provides them. There are basically three types of lenses: soft, hard, and gas-permeable. Soft contact lenses are usually more comfortable to wear, but they also tear more easily than hard contact lenses. Hard lenses also tend to "pop" out more frequently. Gas-permeable lenses are a compromise between the hard and soft, allowing greater comfort than hard lenses but less chance of tearing than soft lenses. Contacts are usually worn during the day and taken out every night for cleaning. Extended-wear lenses allow users to leave in their contacts for longer periods of time, even when they're sleeping. More recently, one-a-day contact lenses are gaining popularity among lens wearers. These contacts are worn for only one day and thrown away, eliminating the hassle of cleaning them every night.

History

The first contact lens was made by German physiologist Adolf Fick in 1887. Fick's lens was made of glass and was a so-called scleral lens because it covered the sclera, the white part of the eye. By 1912, another optician, Carl Zeiss, had developed a glass corneal lens, which fit over the cornea. Two scientists, Obrig and Muller, introduced a plastic scleral lens in 1938. It was made of the material commonly known as Plexiglas. Because it was lighter than glass, the Plexiglas lens was easier to wear. The first plastic corneal lens was made by Kevin Touhy in 1948.

To fit these early lenses, an impression was made of the patient's eyeball, and the lens was formed in the resulting mold. This procedure was doubtlessly uncomfortable, and the lenses themselves were often problematic to wear. Scleral lenses deprived the eye of oxygen, and many of these earlier lenses slipped out of place or popped out of the eye, and were often, oddly enough, difficult to remove. Touhy's first corneal lens had a diameter of 10.5 millimeters, and in 1954 Touhy reduced the diameter further to 9.5 millimeters, resulting in better wearability. Around this time the Bausch & Lomb company developed the keratometer, which measures the cornea, and eliminated the need for eyeball impressions.

The first successful soft contact lenses were developed by chemists in Czechoslovakia. In 1952, professors in the Department of Plastics at the Technical University in Prague set themselves a task of designing a new material that was optimally compatible with living tissue. They did not set out to create contact lenses, but by 1954 the team of Czech scientists had invented what is called a "hydrophilic" (for its affinity to water) gel, a polymer plastic that was suitable for eye implants. The scientists immediately recognized the new

Raw Materials

The raw material for contact lenses is a plastic polymer. (A polymer is a blend of materials created by linking the molecules of different chemical substances.) Hard contact lenses are made of some variant of polymethyl methacrylate (PMMA). Soft contact lenses are made of a polymer such as poly hydroxyethyl methacrylate (pHEMA) that has hydrophilic qualities, that is, it can soak up water and still retain its shape and optic functions. The science of lens material is always being updated by lens manufacturers, and the specific material of any contact lens may differ depending on the maker.

The Manufacturing

Process

Contact lenses may be produced by cutting a blank on a lathe, or by a molding process. The forming of the lens involves shaping the plastic into specified curvatures. The major curves of the lens are named the central anterior curve (CAC) and the central posterior curve (CPC). The CAC refers to the overall curve of the side of the lens that faces out. This outer contour produces the correct refractive change to fit the patient's visual needs. The CPC is the concave inner side of the lens. This conforms to the measurements of the patient's eye. Usually these two curves are formed first, and the lens is then called semi-finished. The lens is deemed finished when peripheral and intermediate curves are formed, and the edge is shaped.

Molding method

-

1 Molding the lens can be carried out in several different ways. The

lenses first developed in Prague were spin-cast. Three different fluids

were poured into open rotating molds. The outside curvature of the lens

was shaped by the mold, and the inside curvature was formed according to

the speed of the rotation of the mold. The centrifugal force of the

spinning mold led to the polymerization of the fluids so that the

molecular chains linked to form the required hydrophilic plastic. A more

reliable mass-production

method is injection molding. In injection molding, the molten plastic is injected into the mold under pressure. Then the lens is removed from the mold and cooled. The lens is then finished on a lathe. It is also possible to produce lenses entirely through molding, that is, they need no lathe cutting. This is a recent development, made possible through highly automated, computer controlled mold production.

Lathe process

-

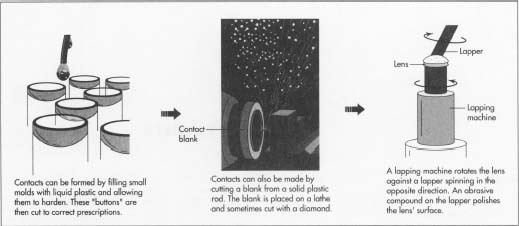

2 The initial forming of the lens can also be done by cutting on a

lathe. First a blank is made. The blank is a circle only slightly larger

than the size of the finished lens. This can be cut from a plastic rod,

or stamped from a plastic sheet. Next the blank is fastened to a steel

button with a drop of molten wax. The button is then centered on a

lathe, which begins to spin at high speed. A cutting tool, which may be

a

diamond

or a laser, makes concave cuts in the blank to form the CPC. Indicators

on the lathe measure the depth of the cuts to guide the lens operator.

The button holding the blank is next moved to a lapping machine. The lapping machine holds the blank against a lapper, which is a revolving disk coated with an abrasive compound. The shape of the lapper matches the CPC of the lens. The lapping machine spins the blank in one direction, and the lapper in the other. It also moves the blank in a small figure eight motion. The abrasion polishes the lens surface.

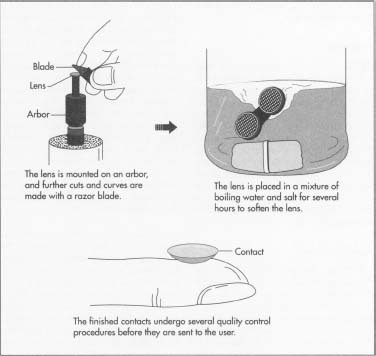

The polished lens is then mounted on a steel shaft called an arbor. The end of the arbor has been ground to match the CPC so the lens will fit on the shaft. The arbor is installed in a lathe, and the operator makes convex cuts in the lens to form the other major curve, the CAC. Now this side of the lens is polished, and the lapper is modified to fit the convex CAC. When this second side of the lens is polished, the lens is considered semi-finished.

Finishing

- 3 The contact lens requires several more curves to be ground before the lens will fit exactly on the patient's eye. The final curves are the peripheral anterior and posterior curves and the intermediate anterior and posterior curves, which govern the shape of the lens nearest and next-nearest the edge. The lens is mounted on an arbor again by suction or with double-sided tape. The arbor is installed in the lathe or grinding machine. These shallower cuts may be ground with emery paper or cut with a razor blade. The diameter of the lens may also be trimmed at this time.

Quality control

- 4 Quality control is very important for contact lenses, since they are medical devices and they must be custom fit. The lenses are inspected after each stage of the manufacturing process. The lenses are examined under magnification for anomalies. They are also measured by means of a shadow graph. A magnified shadow of the lens is cast on a screen imprinted with a graph for measuring diameter and curvature. Any errors in the lens shape show up in the shadow. This process may be automatically performed by computer.

Packaging

- 5 After the lens has passed inspection, it is sterilized. Lens are boiled in a mixture of water and salt for several hours to soften the lens. Next, the lens are packaged. Standard packaging for lenses is a glass vial, filled with a saline solution and stoppered with rubber or metal. The hydrophilic material of soft contact lenses soaks up the saline solution, which is similar to human tears, and becomes soft and pliable. The lenses in this state are ready to wear.

The Future

The material for contact lenses is the subject of much research. Scientists are investigating different chemical recipes that may give plastic more desirable characteristics. One polymer currently being researched is a silicon-oxygen compound called siloxane. Siloxane forms a thin, flexible film and admits oxygen through to the eye 25 times better than current standard soft lenses. There are disadvantages to this compound, however: siloxane does not wet easily and it attracts lipids (fats) to its surface, causing it to cloud. Researchers have found a way to add flourine molecules to the siloxane compound, causing the material to resist lipids. Then they chemically attach a wetting agent, which changes its molecular shape when boiled in a saline solution, so that the material can soak up water like traditional soft lens. This material may ultimately lead to extended-wear contacts that can be worn for weeks at a time.

Researchers are also investigating new polymers that can be used for scleral lenses. For most people, comeal lenses are the norm, but the large scleral lenses are useful for patients with severely damaged corneas. Depending on the eye problem, some patients cannot regain their sight without a corneal transplant, but scleral lenses may help patients avoid eye surgery. Scleral lenses rest on the white part of the eye and form a vault over the cornea itself. This space over the cornea is filled with artificial tears, which serve to smooth out the cornea's damaged surface. In the past, scleral lenses have been uncomfortable because they do not allow enough oxygen to the eye, but investigations into new materials are focusing on more oxygen-permeable lenses.

Material for oxygen-permeable lenses has also been experimented on the space shuttle Endeavour. The designers of the experiment believe that microgravity conditions would promote a lens material that repels debris better and processes oxygen more effectively than polymers made in traditional labs. If commercially feasible, a new generation of contact lenses may be manufactured in space.

Where To Learn More

Book

Ruben, Montague, ed. Soft Contact Lenses: Clinical and Applied Technology. John Wiley & Sons, 1978.

Periodicals

"Making Eye Contact." Ad Astra, September-October 1993, p. 5.

"This Contact Lens Is A Sight For Sore Comeas." Business Week, April 20, 1992, p. 94.

"Extending Extended-Wear Contacts." Science News, September 5, 1992, p. 153.

— Angela Woodward

I have cracked one of the very best email extractors ever built: CBT EMAIL EXTRACTOR.

The original software is priced at 500 GBP but I can offer you the cracked version for only 100 USD. I can also crack all future updates for only 50 USD per update.

I only accept cryptocurrency payments as what I am doing is not exactly legal.

Do let me know if you are interested.

If you want some more info on the software, I suggest that you Google it.

Many thanks