Airship

Background

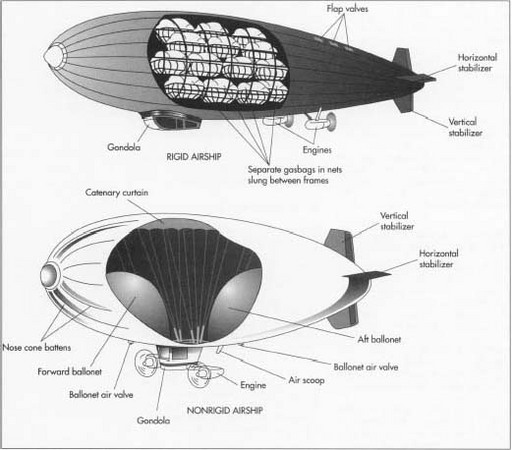

An airship is a large lighter-than-air gas balloon that can be navigated by using engine-driven propellers. There are three types of airships: rigid (has an internal metal frame to maintain the envelope's shape); semi-rigid (rigid keels run the length of the envelope to maintain its shape); and non-rigid (internal pressure of the lifting gas, usually helium, maintains the envelope's shape). This essay focuses on non-rigid airships (commonly called blimps) because they are the primary type of airship in general use today.

History

The history of airships begins, like the history of hot air balloons, in France. After the invention of the hot air balloon in 1783, a French officer named Meusnier envisioned an airship that utilized the design of the hot air balloon, but was able to be navigated. In 1784, he designed an airship that had an elongated envelope, propellers, and a rudder, not unlike today's blimp. Although he documented his idea with extensive drawings, Meusnier's airship was never built.

In 1852, another Frenchman, an engineer named Henri Giffard, built the first practical airship. Filled with hydrogen gas, it was driven by a 3 hp steam engine weighing 350 lb (160 kg), and it flew at 6 mi/hr (9 km/hr). Even though Giffard's airship did achieve liftoff, it could not be completely controlled.

The first successfully navigated airship, La France, was built in 1884 by two more Frenchman, Renard and Krebs. Propelled by a 9 hp electrically-driven airscrew, La France was under its pilots' complete control. It flew at 15 mi/hr (24 km/hr).

Military airships

In 1895, the first distinctly rigid airship was built by German David Schwarz. His design led to the successful development of the zeppelin, a rigid airship built by Count zeppelin. The zeppelin utilized two 15 hp engines and flew at a speed of 25 mi/hr (42 km/hr). Their development and the subsequent manufacture of 20 such vessels gave Germany an initial military advantage at the start of World War I.

It was Germany's successful use of the zeppelin for military reconnaissance missions that spurred the British Royal Navy to create its own airships. Rather than duplicating the design of the German rigid airship, the British manufactured several small non-rigid balloons. These airships were used to successfully detect German submarines and were classified as "British Class B" airships. It is quite possible this is where the term blimp originates—"Class B" plus limp or non-rigid.

Passenger-carrying airships

During the 1920s and 1930s, Britain, Germany, and the United States focused on developing large, rigid, passenger-carrying airships. Unlike Britain and Germany, the United States primarily used helium to give their airships lift. Found in small quantities in natural gas deposits in the United States, helium is quite expensive to make; however, it is not flammable like hydrogen. Because of the cost involved in its manufacture, the United States banned the exportation of helium to other countries, forcing Germany and Britain to rely on the more volatile hydrogen gas. Many of the large passenger-carrying airships using hydrogen instead of helium met with disaster, and because of such large losses of life, the heyday of the large passenger-carrying airship came to an abrupt end.

The first passenger-carrying non-rigid airship was invented in 1898 by Alberto Santos Dumount, a citizen of Brazil living in Paris. Under a sausage-shaped balloon with a ballonet or collapsible air bag inside, Dumount attached a propeller to his motorcycle's engine. He used both air and hydrogen, not helium, to lift the blimp.

The non-rigid airship of the 1940s and 1950s

After the rigid airship disasters of the 1920s and '30s, the United States as well as other countries refocused their attention on the non-rigid airship as a scientific/military tool. Aerial surveillance became the most common and successful use of the blimp. In the 1940s and '50s, blimps were used as early warning radar stations for merchant fleets along the eastern seaboard of the United States. They were also used and are still used in scientific monitoring and experiments.

Although as a company it no longer makes airships, Goodyear is a name sononymous with the manufacture of blimps. During the first half of the twentieth century, Goodyear manufactured over 300 blimps, more than any other airship manufacturer. Goodyear blimps were primarily used by the U.S. Army and Navy for aerial surveillance.

Modern resurgence of the non-rigid airship

Today, non-rigid airships are known more for their marketing power than for their surveillance capabilities. Blimps have been used commercially in the United States since about 1965. Advertising blimps measure about 150,000 cu ft (4,200 cu m). Since blimps can hover over one space and can be viewed over a large expanse with very little noise disturbance, they are excellent mediums for advertising at large outdoor events.

The use of the night billboard on blimps has been quite an advertising fad. The sign is a matte of multicolor incandescent lamps permanently fixed to the sides of the airship envelope, and it can be programmed to spell out different messages. Originally, the signs were developed by electromechanical relay. Now they are stored on magnetic tape, developed by composing equipment on the ground, which are fed into an airborne reader. The taped information is played back through a computer to the lamp driver circuits. The displayed messages can be seen over long distances. In the late 1980s, the use of blimps in advertising exploded. Its popularity does not seem to have let up.

Raw Materials

The envelope is usually made of a combination of man-made materials: Dacron, polyester, Mylar, and/or Tedlar bonded with Hytrel. The high-tech, weather-resistant plastic film is laminated to a rip-stop polyester fabric. The envelope's fabric also protects against ultraviolet light. Usually the envelope is smaller than the bladder to ensure that the envelope takes the load when the blimp is fully inflated. The bladder is made of a thin leak-resistant polyurethane plastic film.

Ballonets are usually made of a fabric lighter than the envelope's because they only retain gas tightness and do not have to withstand normal main envelope pressures. Air scoops channel air to the ballonets.

Blimps obtain much of their lift from lighter-than-air gases, most commonly helium, inside the envelope.

Most of the metal used on the blimp is riveted aircraft aluminum.

Earlier cars were fabric-covered tubing framework. Today's gondolas are made of metal monocoque design.

The nose cone is made of metal, wood, or plastic battens, laced to the envelope.

Design

The main body of the blimp is made up of an inner layer, the bladder, and an outer layer, the envelope. The bladder holds the

Inside the envelope are catenery curtains, which support the weight of the car by distributing the loads imposed by the airship into the fabric of the main envelope. Catenery curtains all consist of cable systems attached to the car, which terminate in the fabric curtains.

The envelope's shape is maintained by regulating internal pressure of helium gas inside. Within the bladder are one or more air cells/balloons called ballonets. These are filled with air (as opposed to the rest of the bladder which is filled with helium) and are attached to the sides or bottom of the blimp. The ballonets expand and contract to compensate for changes in helium volume due to varying temperature and altitude. The pilot has direct control of the ballonets via air valves.

The nose cone serves two purposes. It provides the point of attachment for mast mooring and adds rigidity to the nose (which encounters the greatest dynamic pressure loads in flight). On the ground, the inflated blimp is secured to a stationary pole called the mooring mast. The rigid nose dish is attached to the mooring mast. The secured blimp can move freely around the mast with wind changes. There are

Airship tail surfaces come in three configurations: the cruciform (+), the X, and the inverted Y. These tails are made up of a fixed main surface and a controllable smaller surface on the aft end. These surfaces weigh only 0.9 lb per sq ft (4.4 kg per sq m). Tail fins control flight direction. They are anchored at the rear of the ship and are supported by guide wires. The elevators and rudders also help to guide the blimp's movement and are mounted to the fin's edges with hinges.

The airship car, or gondola, is similar to conventional aircraft construction. The gondola contains a number of lead shot bags which are constantly adjusted based on the crew's analysis. The gondola is attached to the blimp by either an internal load curtain or externally, by being attached to envelope sides.

Inside the gondola, there a series of controls: the overhead control panel containing controls for communications, fuel, and electrical systems; throttles to regulate engine speed and propeller pitch controls to regulate angles at which propeller blades "bite" the air; fuel mixture and heat controls to regulate the degree to which fuel is mixed with air in engine; temperature controls to prevent icing; envelope pressure controls to regulate helium and ballonet air pressure; communication equipment; main instrument panel; rudder pedals to control right/left direction of blimp; elevator wheels to control up/down direction of blimp; navigational instruments; and color weather radar.

The Manufacturing

Process

Envelope

- 1 The envelope is made of patterns of fabric panels. Two or three plies of cloth are impregnated with an elastomer. One of these plies is placed in a bias direction with respect to others. The pieces of the envelope can be put together in a number of ways. They can be cemented and sewn together, or heat-welded (heat-sealed).

- 2 The outside of the envelope is coated with aluminized paint for protection against sunlight. The envelope will have the required shape when filled with gas.

- 3 The catenery curtains are attached on to the main envelope proper in a similar manner.

- 4 The bladder is formed from strips that are welded together.

- 5 The tail construction consists mostly of lightweight metal structural beams covered with doped fabric. They are held to the envelope by cables which distribute the load into fabric patches cemented or heat-welded to the envelope proper. They are not directly attached to the envelope in the manufacturing process, but put on when the blimp is inflated.

Gondola

- 6 The frame of the gondola is made of material similar to the tail construction, covered with doped fabric.

Inflation

The erection of the blimp takes only a short amount of time. (The following is only one method of inflation. There are variations on this method.)

- 7 The envelope is spread out on the floor of the airship hangar, with a net placed over it. This net is held down by sandbags. Gas is fed into the enveloped from tank cars each containing 200,000 cu ft (5,700 cu m) of 99.9% pure helium compressed to 2100 psi (14.5 megapascals). The net is allowed to slowly rise, with the envelope underneath it.

- 8 Fins, nose cone, battens, air valves, and helium valves are attached while the envelope is still near the ground. After these parts are attached, the envelope is allowed to rise high enough to permit rolling the gondola underneath it. After the gondola is attached, the net is removed and the airship is rigged for flight.

Shipping

- 9 When transported, the uninflated fabric envelopes can be folded, shipped, and stored in a space that takes up less than 1% of its inflated volume. This feature makes the non-rigid airship more practical than a rigid one.

Quality Control

A blimp requires a big crew, especially on the ground. Pilots must be certified in planes or helicopters and undergo special lighter-than-air pilot training. The FAA requires a separate license to command a blimp. As of 1995, there were only about 30 active blimp pilots in the world. Many blimps require 24-hour monitoring. The envelope and ballast are checked every hour to make sure the proper equilibrium is maintained.

The Future

Propulsive efficiency will be improved by using lightweight, two-stroke aviation diesel engines, gas turbines, or solar energy. New bow and stem thrusters will be developed to improve maneuverability. New lightweight plastics might change the hull design. More lightweight, high strength materials will probably be developed and inevitably improve the overall design and function of the airship. The Pentagon and the U.S. Navy have renewed interested in developing blimps for various defense, missile surveillance, radar-surveillance platforms, and reconnaissance purposes.

Where to Learn More

Books

Botting, Douglas, et al. The Giant Airships. Time-Life Books, 1980.

Ventry, Lord and Eugene M. Kolesnik. Airship Saga: The history of airships seen through the eyes of the men who designed, built and flew them. Blandford Press, 1982.

— Annette Petrusso