Pillow

Background

Americans usually have two or three pillows on their bed. Today, pillows are stuffed primarily with materials such as polyester (a synthetic), feathers, down, or a combination of the latter two. The least expensive pillows to manufacture are polyester, although they are the most durable, easily washed, and cause few allergic reactions. The most expensive is the pillow filled with goose down. Feathers are a moderately priced stuffing. Some higher-end pillows may be filled with a combination of goose feathers and down, and that ratio may be varied extensively according to price point (the more down, the more expensive). The pillow filling is distinguished by the tag on the pillow casing, which must be there by law in the event that the consumer may be allergic to the contents.

Pillows are still manufactured in great quantities in the United States. They are also produced outside the country, but pillows are generally not imported to the United States. Shipping is measured by volume and pillows are extraordinarily expensive to ship. Some manufacturers have tried to have pillows made out of the country—where labor is cheaper—and crush the pillows during transportation in order to save money. However, once the pillow is crushed, it is difficult for it to spring back to its original shape and much of its plushness is lost.

History

The shape and contents of pillows have varied little over time. The wealthier Greeks rested their heads and feet upon richly embroidered cushions and bolsters. The Egyptians, regarding the head as the seat of life, lavished much attention, detail, and money on pillows for the dead. The Chinese, however, thought that soft pillows robbed the body of vitality, and their pillows were made of wood, leather, and ceramic materials. Some were even filled with herbal remedies to cure disease, turn white hair black, restore lost teeth, and inspire sweet dreams.

For centuries, people slept fairly upright with not only a pair of pillows on the bed but a large, cylindrical bolster as well. These bolsters, sometimes nearly the width of the bed, were stuffed with down or some other type of batting and closed up. They were placed against the headboard and were the foundation for the pillows. Then, a pair of pillows was placed upright against the bolster. The sleeper would prop himself up against these pillows, resulting in a sleeping position that was closer to sitting than reclining. Until about the mid-1800s it was thought this position was better for the body.

Other fancy pillows were found on beds of the nineteenth and early twentieth centuries. Sometimes large, square pillows were placed within a decorative pillow cover and then placed against the pillows actually used for sleeping on a bed. These were often removed from the bed before sleep. Until cotton became easy to obtain around 1840, American women showed their needlework prowess by carefully hand weaving and sewing linen pillow cases and marking them with their initials and the number the case was within a set of pillow cases. As the American textile industry flourished throughout the 1800s, covers for pillows (which housed the stuffing) went from utilitarian linen to the sturdy cotton ticking, still seen on pillows and in fabric stores.

The traditional filler for pillows was, until recently, down and feather. However, as fabrics changed, so too did yarns. Synthetic polyester filling has replaced natural batts as it is has acceptable loft and shape retention, is relatively inexpensive, may be washed, and few people are allergic to it.

Raw Materials

The batting, or filling, itself is the most important part of the pillow. The most expensive filling is down. This is the light, fluffy undercoating of waterfowl, consisting of clusters of filaments growing from a central quill point. Down has a quill point but no quill shaft and is more resilient as a result. It is three-dimensional and therefore has more loft. Thousands of clusters are found in down that trap warm air to prevent heat loss. Duck down is smaller, more plentiful, and less expensive. It is important to note that not all down is the same. Down is rated by fill power, which is the volume of space in a calibrated cylinder that 1 oz (28 g) measures. The higher the number, the better the fill power.

Feathers are the principal covering of birds. They are flat and two-dimensional with a hard, tubular quill shaft that runs from one end to the other. Because they are flat, they are unable to effectively trap air and warmth. Feathers are strong, but not terribly soft. Duck feathers are the most common type of feather used in American pillows. Many manufacturers combine down and feather to make an affordable, comfortable pillow.

An other type of filling is polyester, a synthetic material. The cheapest polyester used for pillows is a continuous solid filament polyester which has good initial shape but loses loft fairly shortly. A better grade of polyester is called hollofill, which is also a continuous filament fiber but has a hollow core that gives the pillow more loft for a greater period of time than cheaper grade polyester.

The pillow filling determines the fabric chosen for the pillow casing. While the casing is generally cotton or cotton-polyester, the weight and closeness of the weave varies according to filling. The feather and down filling require a more expensive, very dense, tightly woven fabric that will keep the feather shafts from poking the sleeper and keep the fine down from working its way through the cloth. Polyester batts do not require such closely woven fabrics. These fabrics may have a starch placed on them during their manufacture to make them stiffer and more resistant to penetration. The only other material required for pillow manufacture is a sturdy thread for sewing the pillow itself.

The Manufacturing Process

The following process will describe the construction of a polyester-filled pillow, an inexpensive and commonly produced pillow. It is a small-medium size operation which produces between 2,000-3,500 pillows every day. The largest manufacturers of American-made pillows produce between 10,000-15,000 pillows each day.

- The pillow covering must be constructed first. Sturdy cotton or cotton-polyester fabric is shipped to the factory in huge bolts. The fabric must be treated or calendared so that the sewn casing may be blown apart and easily separated during filling. Once calendared the fabric is taken to huge tables and cut apart—dozens of layers at a time—with either heavy shears or fabric cutting machines.

- Stacks of rectangular-shaped fabric are taken to the sewing machines. In fully automated plants, automatic sewing machines are used to grab the fabric and sew them together. These machines are quite expensive and many plants still opt for people to do this work. In this case, a machine operator takes two pieces and sews them together around the edges, leaving a space of approximately 6 in (16 cm) open in order to stuff the pillow. As the operator sews the edges together, the tag that lists the pillow's contents is attached. The operator then turns the pillow covering inside out so that the seams are on the inside of the case.

-

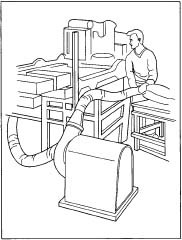

The casings are moved to the pillow machine, which blows the polyester

filling into the pillows. The machine has been loaded with polyester in

one of two ways. More expensive machines need only to have an entire

bale (about 600 lb [272 kg]) of polyester inserted into the machine and

the machine unloads and combs it. Less expensive machines require an

operator to unload

baled and tightly packed polyester by hand. Once the polyester is inside the machine, the blowing machine combs the polyester so it is fluffy and has some loft. The 6-in (15-cm) opening in the pillow covering is slipped onto a tube on the machine. Then, a blower pushes the polyester into the casing. Some machines can fill up to 100 pillows an hour.

The blowing machine blows polyester filling into a pillow case.

The blowing machine blows polyester filling into a pillow case. - When the pillow is filled, it is taken to another station and workers close the opening in the pillow case using an industrial sewing machine. The pillow is weighed at that time to ensure that it includes the requisite amount of batting.

- The completed pillows are moved to machines for bagging them. The machine blows air into thin plastic bags to open them up and then inserts individual pillows. The bagged pillows are placed into boxes, ready for shipping.

Quality Control

The process described above is really quite labor-intensive as it includes many workers on the floor of the factory in order to fulfill the requirements of manufacturing pillows. As a result, these operators are able to scrutinize the quality of virtually all aspects of the manufacturing process. Operators are vigilant that the dozens of layers of fabric are carefully put down on the cutting table so that the fabric is not askew prior to cutting. This guarantees that the casings can be quickly and evenly sewn. Sewing the casing of the pillow requires careful work and is monitored by supervisors as well as sewers. Polyester batting must be de-baled by hand (metal bands are removed from the large bales) and are examined to ensure that the quality is suitable for pillow inclusion. As operators load the blowing machine with polyester they examine the equipment for defects and inefficiencies. Workers are present as the pillows are blown with batting. Then the stuffed pillows are weighed to ensure that they are the weight represented in the labeling.

Byproducts/Waste

The primary byproducts of the polyester-filled pillows is the metal baling bands used to bundle and transport the polyester batt. This metal is desirable for recycling; one company has neighborhood recyclers pick this up free of charge and recycle it (they may be paid a fee for the scrap metal). Cartons are picked up for recycling a well. Because the fabric is generally produced and calendared elsewhere, bleaches and finishes are not a part of this operation. Polyester fibers themselves are not prone to becoming minute airborne fibers. The 2-in (5.8-cm) or 3-in (7.6-cm) cut lengths of fiber generally do not get into operators' lungs and are not the health-hazard that other fillings are. Down, with its very short filaments, creates a great deal of down dust, and it is imperative to use masks to protect the lungs when working with down and, to a certain extent, feathers.

The Future

Pillows have varied little since they were first used. They are now also made with blends of hypo-allergenic fibers so that even people with allergies or extremely sensitive skin are able to enjoy their comfort. In this age of therapeutic remedies, some pillows are reverting back to the Chinese method of including herbs to relieve aliments and give a better nights rest. Orthopedic pillows are also advancing rapidly. They are filled with or surrounded by foam (some even contain gel or water that can be heated or cooled) that is either already formed or forms around the head, to fully support the neck. These pillows help to relieve neck, back, and lumbar pain. Some help to keep the head elevated to relive congested lungs, sinus problems, and puffy eyes. One company even markets a pillow with an undetectable speaker built in that plugs into the headphone outlet in a stereo.

Where to Learn More

Books

Harris, Eileen. Going to Bed. London: The Victoria and Albert Museum, 1981.

Nylander, Jane. Our Own Snug Fireside. New Haven: Yale University Press, 1994.

Other

Harris Pillow Company. http://www.harrispillow.com (January 2001).

Royal Pillow Company. http://www.royalpillow.com (January 2001).

The Pillowtalker. http://www.pillowtalker.com (January 2001).

— Nancy E.V. Bryk

Thank you for your help

Our pillow casings are 100% cotton. The pillow is completely machine washable and dryable. Inside, our pillow consists of a patented three-tier Flexible Polyurethane Foam System. Flexible Foam Products Polyurethane Foam is a fully cross-linked reaction product of polyhydroxy polyol, toluene diisocyanate, catalysts, surfactants, pigments and water. The Polyurethane Foam product is a polymeric material consisting of repeating units of carbon, hydrogen, oxygen and nitrogen.

There are three different sizes of fill in the pillow. The larger size will provide the appropriate support needed to maintain the health of your cervical nerves. The smaller size provides softness. The middle size is key and is what interlocks each component together, so when you lay down on the pillow it maintains its shape, without being too stiff or too soft. The fill will stay in the position you adjust it to the whole night, providing you with the perfect level of support, and allowing you to rest peacefully until you wake, refreshed the next morning!